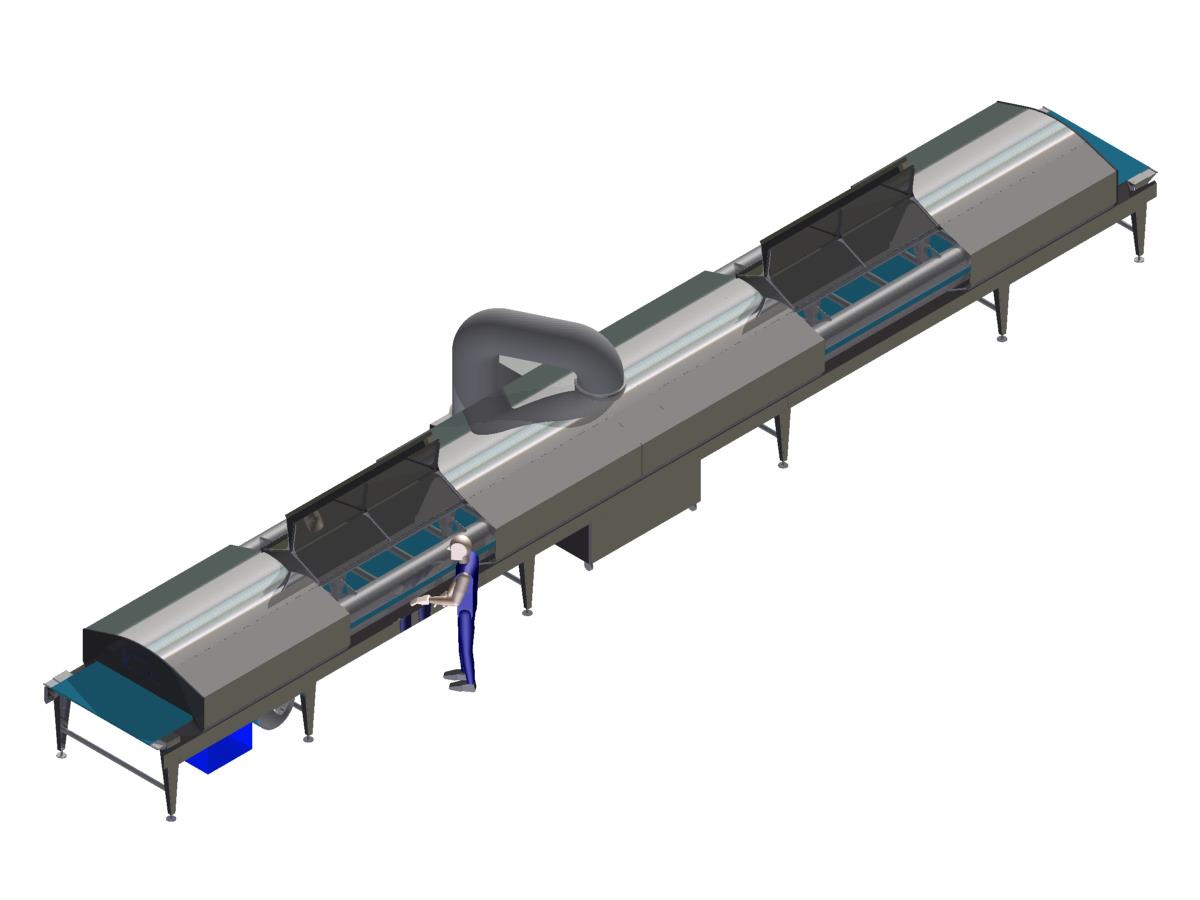

Modular Construction

- Conveyor widths from 300mm to 2000mm.

- Easily transportable 4000mm long modular sections.

- Insulated hinged tunnel covers 2000mm long.

- Slot in air conditioning and temperature control system.

- System designed for fast and easy ‘drop in’ installation.

Hygienic Design

- Cleanable stainless steel construction throughput with a minimal amount of flat horizontal surfaces.

- Minimal product build up areas within the conveyor and easy access for cleaning.

- Full access to product and service areas via gas strut assisted covers.

- All tunnel covers have a self-sealing lip design.

- Stainless steel rollers. Drive drum removable for cleaning on most models.

Specialist Conveyor Design

- A wide range of conveyor belts available, with belting materials carefully selected to suit individual process requirements.

- Automatic belt tracking and tensioning with options for continuous cleaning.

Process Cooling Design

- The standard air conditioning unit can accommodate up to 70 kW of cooling capacity.

- Brine or direct expansion (DX) refrigeration systems are optional.

- Air circulation volumes 2.7m3/sec can be handled in the standard configuration.

- Optional dehumidification by air reheating or dehumidifiers.

- High performance cooling via carefully pitched air knives.

- Gentle cooling velocities achieved by flow and counterflow air directions.

- Under belt cooling available via pressurised coils.

The cooling shall be accomplished via either a direct expansion system using refrigerant or via a water chilled system.

The refrigeration system will be sized and integrated into the tunnel

design.